Successfully managing an FR clothing program and properly protecting your workforce comes with many challenges. At Mount Vernon FR, we’re here to help you. The links below offer a number of resources as you navigate the terminology, standards, test methods and many flame resistant fabric options available to you. Still have questions? We’re only a phone call away.

Learn more about Arc Flash & Flash Fires

Frequently Asked Questions

-

How is flame resistance measured?

The basic test for flame resistance is ASTM D6413. In this test fabric specimens are exposed to a flame for 12 seconds followed by tearing the damaged area with a small weight. The length of the damaged area is measured and reported as char length. If a fabric continues to burn after the 12 second exposure has ended this burning is timed and reported as afterflame time. Every lot of our flame resistant fabric is tested by this method before and after 100 industrial wash and dry cycles to confirm the durability of the flame resistant properties.

-

What other tests are conducted on your FR fabrics?

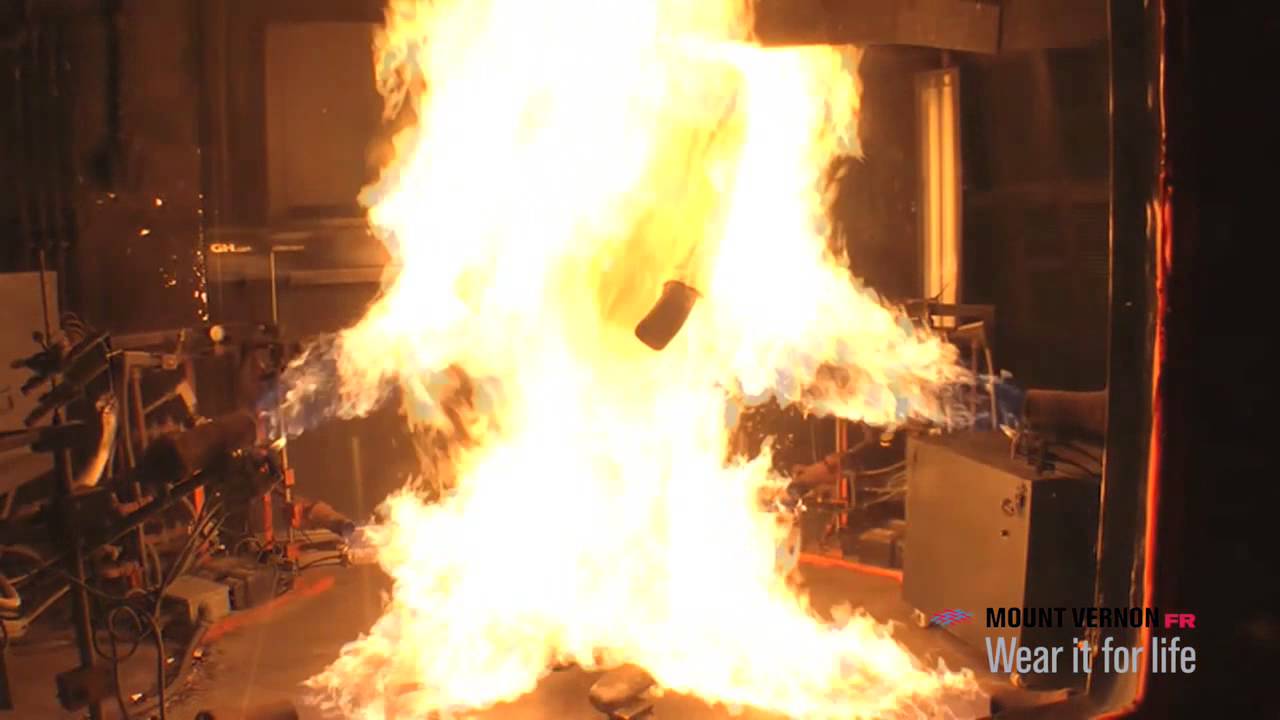

In addition to the Vertical Flammability Test (ASTM D6413), we use the Kinectrics Laboratories in Toronto for electric arc testing by ASTM F1959. Our fabrics are also tested on the thermal manikin at North Carolina State University known as Pyroman™ as part of the requirements for NFPA 2112. We also use Underwriters Laboratories for 3rd party testing and component recognition to standards like NFPA 2112 and CGSB 155.20.

-

Who uses your FR fabric? Where do your FR fabrics wind up?

Mount Vernon FR is proud to partner with some of the best in the business. Many of the world’s leading apparel manufacturers and brands turn to Mount Vernon FR for their flame resistant fabric needs. Click here to check out who’s using Mount Vernon FR. Our flame resistant fabrics are used for retail and rental uniforms, military applications, and for workwear that is compliant to ASTM F1506 as required for NFPA 70E clothing, which is the standard for electrical safety in the workplace, and NFPA 2112, which is the standard for flash fire protection.

-

What are some of the benefits of producing FR fabrics in the U.S.?

Our U.S.-based capacity allows us to continue to provide consistent 8–10 week delivery of our flame resistant fabrics while also maintaining in-stock inventory on core products and colors that will be available for immediate shipment.

-

How do you ensure your quality?

More than 3,500 computer-monitored control points and extensive quality assurance testing ensure that our FR fabric will be produced with the highest level of reliability, quality, durability, color consistency and shrinkage control.

-

What is the difference between fire retardant fabric and flame resistant fabric?

Flame resistance is the characteristic of a fabric to resist ignition and to self-extinguish if ignited. Flame retardant refers to a chemical substance used to impart flame resistance. Simply put, flame retardant materials may be used to make fabrics flame resistant.

-

What key points should I consider when choosing FR garments?

You should consider the following FR performance properties for your particular job and verify with your employer:

- Arc rating

- Predicted % body burn

- Weight

- Blend

- Comfort stretch properties

- Water repellant properties

- Extended Durability

-

How many FR fabrics do you offer?

Customers can choose from more than 69 standard FR fabrics offered under our AMTEX, RESILIENCE, PHOENIX, FLEXTEX and NANUQ brands. However, with our unique My•FR program, your choice is really unlimited – we can customize an FR garment program to the specific needs of your workforce. We have more than 50 fabrics that are component recognized to the NFPA 2112 standard for flash fire protection. These products are also compliant with the requirements of ASTM F1506 for electric arc protection. Click here to see our fabric collections.

-

Why does fabric selection matter?

Protective performance starts in the fabric, so it’s imperative to specify FR fabrics that focus on the hazards of your workplace. We have the largest selection of comfortable, cotton-rich FR fabrics made in the U.S.A. so you can find the perfect fit for your needs. With so many options, your workforce will not sacrifice comfort or styling for FR protection.

-

Are your FR products guaranteed?

Yes. The durability of the flame resistance of our FR fabric is guaranteed for the life of the garment, provided that all recommended laundering instructions are followed.

-

What are your recommended laundering instructions?

Download Mount Vernon’s Preferred Laundry Guide and FR Care and Maintenance Guide for more information.

FR Terms Explained

- ARC RATING

- ARC THERMAL PERFORMANCE VALUE (ATPV)

- BREAKOPEN THRESHOLD ENERGY (EBT)

- CALORIE

- CELLULOSE

- COTTON

- ELECTRIC ARC FLASH

- FLAME RESISTANCE

- FLAME RETARDANT

- FLASH FIRE

- FR and AR

- HEATFLUX

- INHERENTLY FLAME-RESISTANT FABRICS AND TREATED FABRICS

- LYOCELL

- META-ARAMID

- MODACRYLIC

- NYLON

- PARA-ARAMID

- POLYMER

- PPE (Personal Protective Equipment)

- SPANDEX

- STOLL CURVE

ARC RATING

The value attributed to materials that describes their performance to exposure to an electrical arc discharge.

Source: ASTM F1959 (American Society for Testing and Materials).

The arc rating expressed in cal/cm2 describes the protection provided the wearer against the thermal energy from an electric arc flash. The arc rating may be an ATPV or EBT based on the fabric’s response to thermal energy.

ARC THERMAL PERFORMANCE VALUE (ATPV)

The incident energy, expressed in cal/cm2, on a material or a multilayer system of materials that results in a 50% probability that sufficient heat transfer through the tested specimen is predicted to cause the onset of a 2nd degree burn injury based on the Stoll curve. Source: ASTM F1959.

BREAKOPEN THRESHOLD ENERGY (EBT)

The incident energy on a material or material system that results in a 50% probability of breakopen. Source: ASTM F1959.

While ATPV and EBT describe different responses to electric arc flash, both may be considered the arc rating of a fabric. Both values can be determined for a fabric or layered system, but the lower of the two values is reported as the arc rating. The EBT is sometimes thought to be less desirable than ATPV, but both are a fair measure of the protection provided by a fabric. Woven fabrics will typically have ATPV ratings while some knits, especially fleeces will report an EBT. Fabrics with more strength than insulation will usually have an ATPV while fabrics with more insulation than strength will have and EBT.

CALORIE

The amount of energy needed to raise one gram (or cubic centimeter or one milliliter) of water 1 degree Celsius. Caloric values of food are measured in kilocalories, which is equivalent to 1,000 calories.

In arc testing, energy per unit area is reported as calories per square centimeter (cal/cm2). This is also the format for reporting the arc rating of a fabric. Heatflux may be reported in cal/cm2/sec.

CELLULOSE

A carbohydrate that makes up the cell walls of all plants. Cellulosic fibers and fibers made from cellulose include cotton, rayon and lyocell.

Tencel® is the branded lyocell fiber produced by Lensing. It is a cellulosic fiber made from purpose-grown trees by an energy efficient, environmentally friendly process employing a non-toxic solvent that is recovered and reused.

COTTON

A natural staple fiber that is almost pure cellulose. Cotton is one of the most important and most widely used textile fibers in the world. Cotton is valued for textiles for its versatility, softness, strength, absorbency and dyeability.

Mount Vernon FR offers the most choices in comfortable, cotton-rich FR fabrics made in the U.S.A.

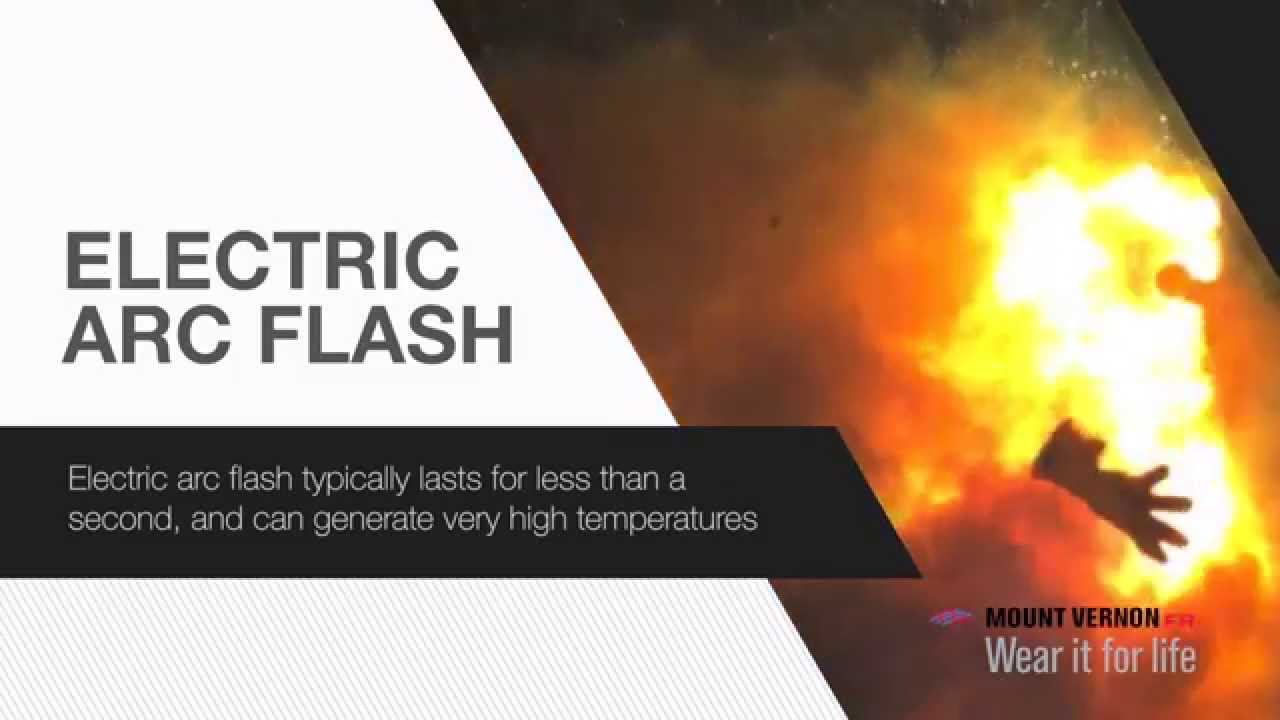

ELECTRIC ARC FLASH

Is not an electrical shock, it is an electrical discharge through air, from a high voltage source to another conductor or ground that typically lasts less than 1 second.

An electric arc flash can generate temperatures high enough to melt nearby plastics and metals and can damage the electric circuits involved. Extremely high radiant energy from the arc can cause 2nd and 3rd degree burns on exposed skin and ignite flammable clothing. Burns can even occur through clothing.

FLAME RESISTANCE

The property of a material whereby combustion is prevented, terminated, or inhibited following the application of a flaming or non-flaming source of ignition, with or without subsequent removal of the ignition source. Source: NFPA 2112 (National Fire Protection Association).

FLAME RETARDANT

A chemical substance used to impart flame resistance. A flame retardant may be added to a fabric to make it flame resistant. Source: Bulwark Industry Update.

FLASH FIRE

A type of short-duration fire that spreads by means of a flame front rapidly through a diffuse fuel, such as dust, gas, or the vapors of an ignitable liquid, without the production of damaging pressure. Source: NFPA 2112 standard.

Flash fires are most common in the oil & gas industry and the natural gas utilities industry.

FR and AR

Clothing that resists ignition and can self-extinguish may be described as flame resistant or FR. Clothing made from materials that have also been arc tested to establish an arc rating may also be described as arc rated or AR.

Only materials that have been tested for flame resistance by ASTM D6413 and have char lengths of less than 6” (150 mm) and afterflame of less than 2 seconds may be arc tested by ASTM F1959. This means that all AR materials are FR, but not all FR materials may be AR (some FR materials may not have been arc tested). Protective garments made from Mount Vernon FR fabrics will be both FR and AR.

HEATFLUX

The thermal intensity indicated by the amount of energy transmitted divided by area and time kW/m2 [cal ⁄cm2s]. Source: ASTM F1959

In thermal testing the heatflux is a measurement of the rate of energy transfer. In some thermal tests in NFPA 2112 and heatflux of 2 cal/cm2/sec (84kW/m2) is used for testing.

INHERENTLY FLAME-RESISTANT FABRICS AND TREATED FABRICS

Flame resistant fibers and fabrics can generally be divided into two groups: those that are inherently flame resistant, and those that achieve flame resistance through special treatments. Inherently flame resistant fibers/fabrics are those where flame resistance is an essential characteristic of the fiber from which textiles are made. Treated fibers/fabrics have an applied chemical treatment to change the original level of a specific property or properties, in this instance flame resistance. Source: Bulwark Industry Update.

Treated fabrics may also incorporate some inherent fibers to improve or impart additional properties.

LYOCELL

A cellulosic fiber made from purpose-grown trees by an energy efficient, environmentally friendly process employing a non-toxic solvent that is recovered and reused. Tencel® is the branded lyocell fiber produced by Lensing.

Lyocell fiber properties are similar to but typically exceed cotton for strength, absorbency and elasticity. This makes lyocell an excellent blending partner for cotton.

META-ARAMID

A synthetic polymer known for high strength and its inherent resistance to heat and flame. These fibers are dyed by use of a solvent at elevated temperature.

Nomex® is a branded meta-aramid fiber produced by DuPont.

MODACRYLIC

A synthetic polymer comprised of less that 85% but at least 35% by weight of acrylonitrile groups. Modacrylic fibers are inherently flame resistant but sensitive to heat and commonly blended with other fibers like cotton. Protex® is a family of branded modacrylic fibers produced by Kaneka.

Fibers containing 85% or more acrylonitrile groups are called acrylic. The name modacrylic comes from the term “modified acrylic” as the acrylic fiber is modified to make it flame resistant.

NYLON

A synthetic polymer characterized by its strength, flexibility, toughness, elasticity, abrasion resistance and dyeability. Nylon is incorporated in FR fabrics to increase durability, especially resistance to abrasion. Nylon is known as a polyamide (PA) in Europe.

PARA-ARAMID

A synthetic inherently flame resistant polymer with high strength and heat resistance properties. Although not dyeable by conventional methods, small amounts are added to FR fabrics to increase thermal performance or abrasion resistance.

Kevlar® is a branded para-aramid fiber produced by DuPont.

POLYMER

The name given to high molecular weight long chain molecule comprised of many repeats of a basic structure known as a monomer.

PPE (Personal Protective Equipment)

Equipment worn to minimize exposure to hazards that cause serious workplace injuries and illnesses. These injuries and illnesses may result from contact with chemical, radiological, physical, electrical, mechanical, or other workplace hazards. Source: OSHA.

The 2018 edition of NFPA 70E designated arc rated clothing as PPE.

SPANDEX

A synthetic elastomeric polymer consisting of at least 85% by weight of polyurethane. This fiber can be used to impart stretch properties to specially designed flame resistant fabrics to increase comfort and range of motion. Lycra® is a branded spandex produced by Invista.

Although the fiber is flammable, small amounts of spandex can be used in FR garments. Higher amounts of spandex in a fabric do not guarantee higher levels of stretch. Fabric construction and spandex content determine the stretch properties of a fabric.

STOLL CURVE

An empirical predicted second-degree skin burn injury model, also commonly referred to as the Stoll Response. Source: ASTM F1959.

The Stoll curve established a relationship between human skin response to thermal energy and the response of a copper calorimeter to the same energy levels. This relationship allows for study of thermal properties of materials without burn injury to humans or animals.